Products

Products

Your Trusted Partner in Precision Extrusion

Kesar Extrusions specializes in manufacturing high-quality screws and barrels tailored for optimal performance across various industrial applications.

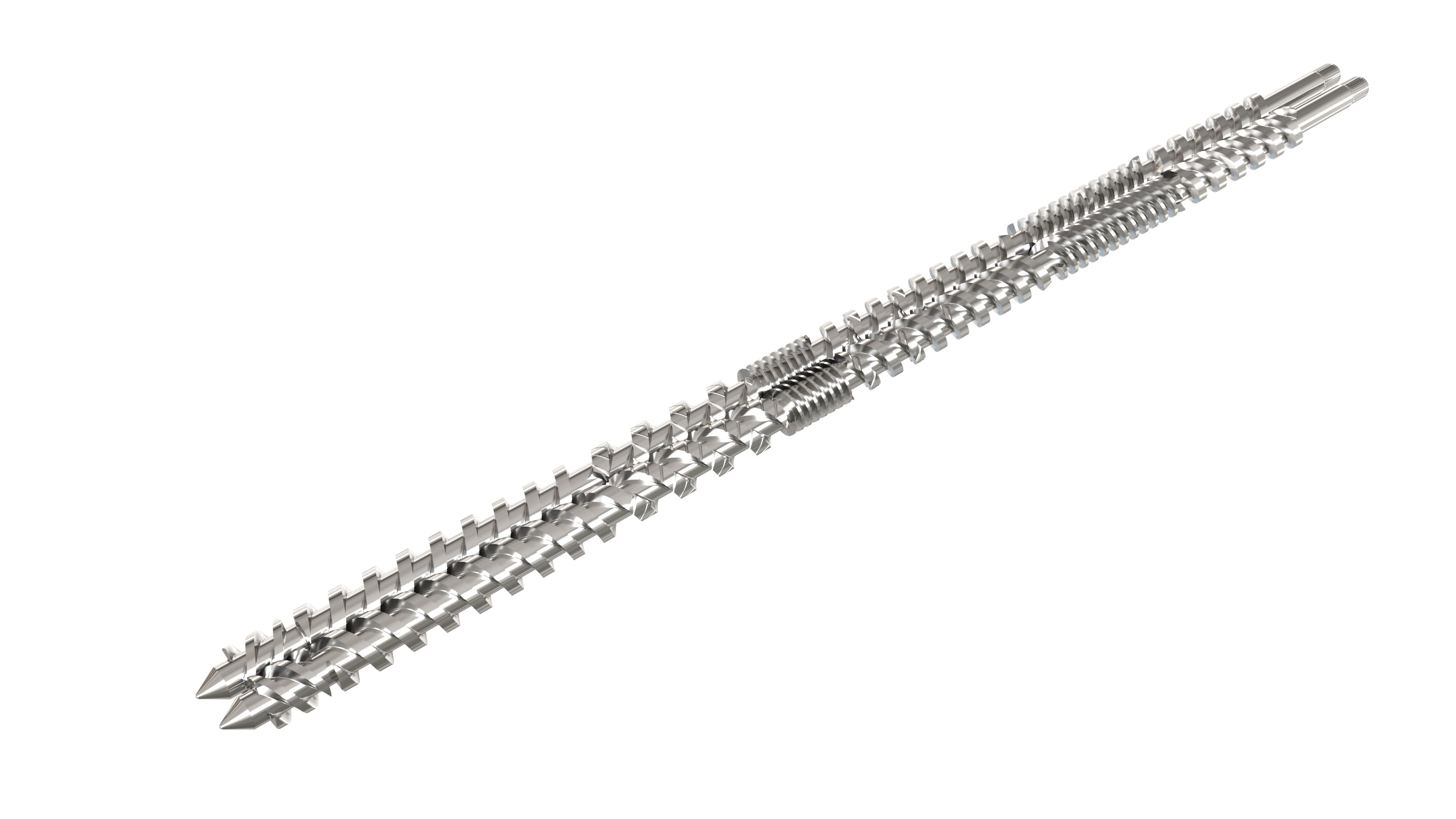

PARALLEL TWIN SCREW & BARREL

Driven by the latest technology, all products offered by Kesar Extrusions largely contribute to efficient functioning of high-end industrial equipments. Below are some of its offerings:

Kesar Extrusions manufacturers parallel twin screws and barrets with a screw diameter of up to 150mm. We offer screws and barrels that rightly meet altre necessary technical specifications. This makes us one of the few companies to offer the most precise parallel twin screw and barrel.

Nitrided :

| DIN | Make | AISI | Nitriding Hardness | Nitriding Depth |

| EN 41B | Sanyo Special Steel | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm |

| 41CrAlMo7 | – | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm |

| 34CrAlMo5 | – | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm |

| 31CrMoV9 | – | 4140 | 65 – 68 HRC | 0.6 – 0.7 mm |

Hard Chrome Plated:

| DIN | Make | AISI | Layer | Hardness |

| EN 41B | Sanyo Special Steel | 1040 | 0.025 – 0.10 mm | 65-68 HRC |

| 41CrAlMo7 | – | 1040 | 0.025 – 0.10 mm | 65-68 HRC |

Hard Face Coating/ PTA Welding:

| DIN | Surface Depth | Hardness | Ra µ M |

| EN 41B | Upto 2.00 mm | 62 – 65 HRC | 0.2-0.4 |

| 41CrAlMo7 | Upto 2.00 mm | 62 – 65 HRC | 0.2-0.4 |

| 34CrAlMo5 | Upto 2.00 mm | 62 – 65 HRC | 0.2-0.4 |

| 31CrMoV9 | Upto 2.00 mm | 62 – 65 HRC | 0.2-0.4 |

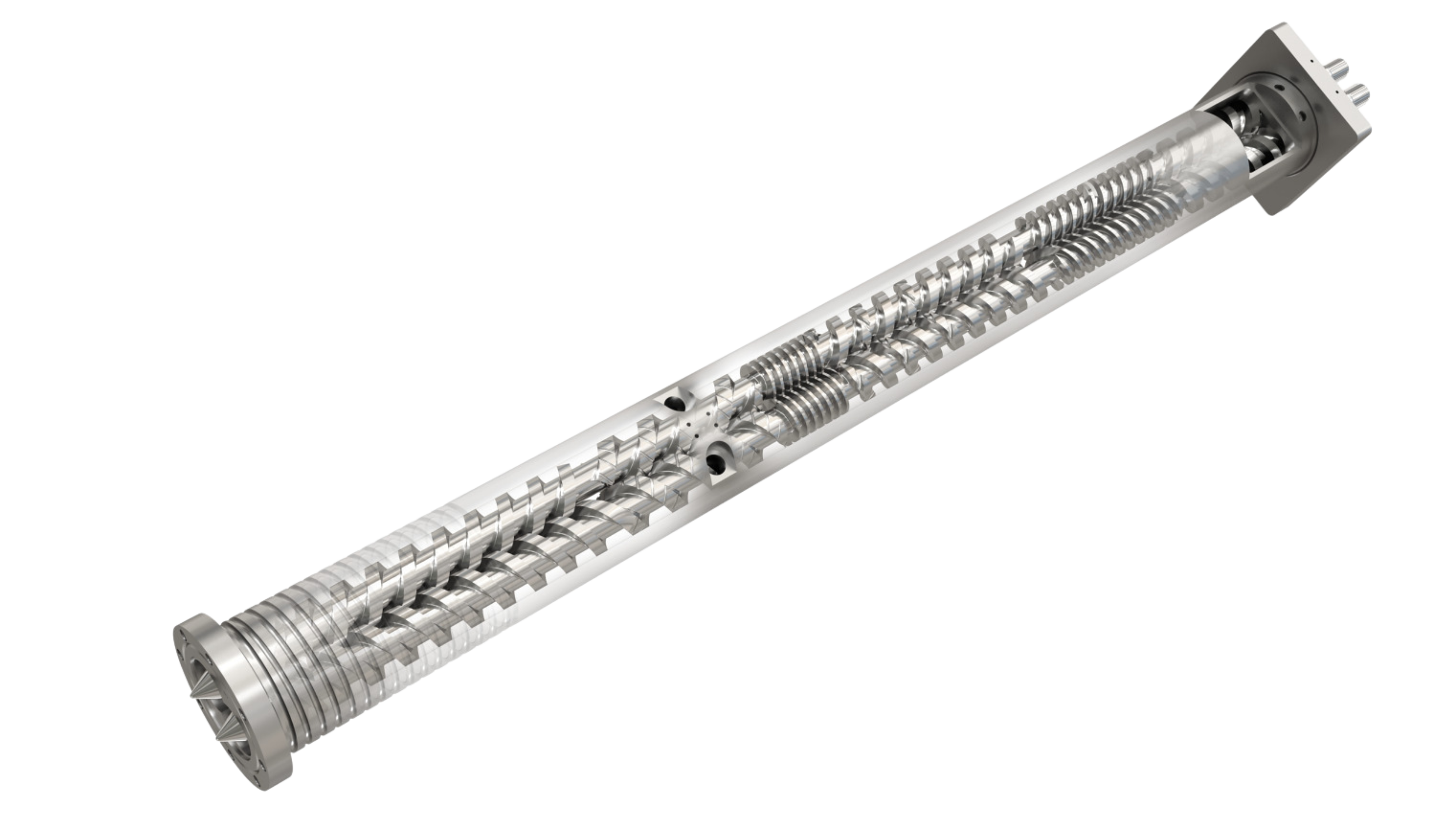

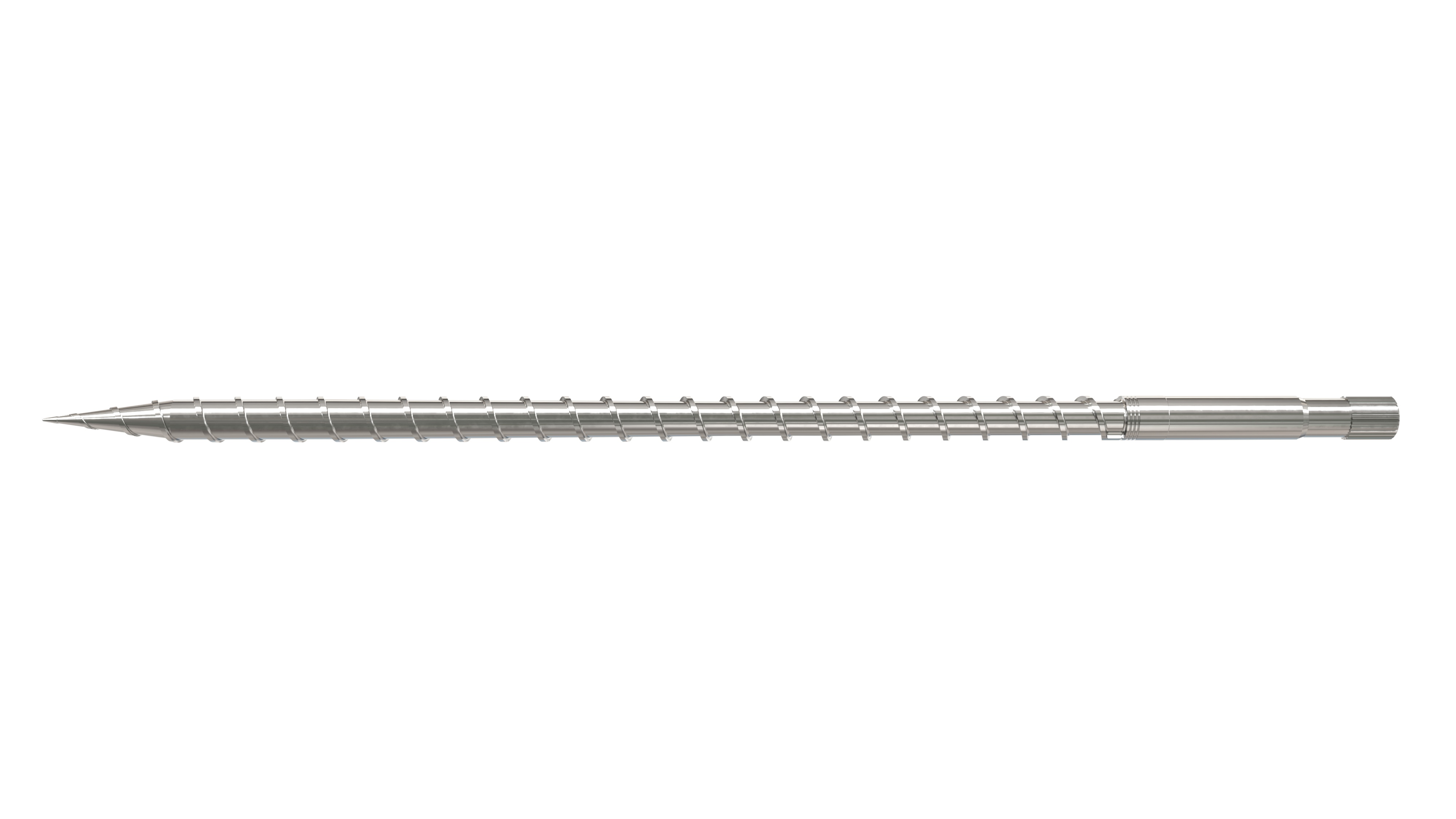

SINGLE SCREW AND BARREL WITH VACCUM PORT

| DIN | Make | AISI | Nitriding Hardness | Nitriding Depth | Ra µ M |

| EN 41B | Sanyo Special Steel | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm | 0.2 – 0.3 |

| 41CrAlMo7 | – | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm | 0.2 – 0.3 |

| 34CrAlMo5 | – | 1040 | 65 – 68 HRC | 0.6 – 0.7 mm | 0.2 – 0.3 |

| 31CrMoV9 | – | 4140 | 65 – 68 HRC | 0.6 – 0.7 mm | 0.2 – 0.3 |

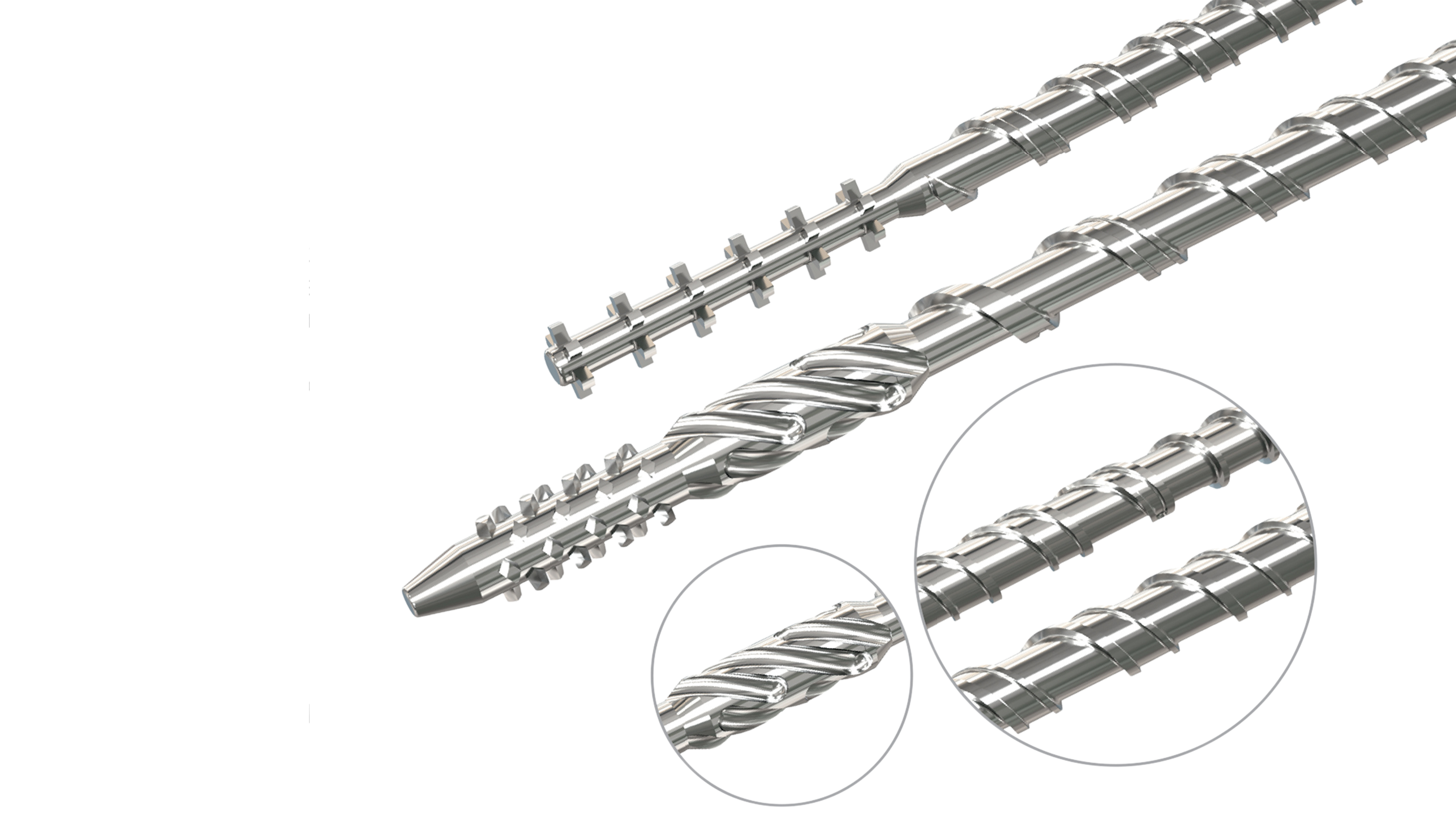

BARRIER MADDOC PROFILE & BARRIER MIXING PROFILE

A single barrier screw efficiently separates melted material from non-melting material into distinct channels. This allows for homogenization of the melted material while maintaining a consistent temperature. Mixing is achieved through an undulating root profile in the screw’s metering zone.

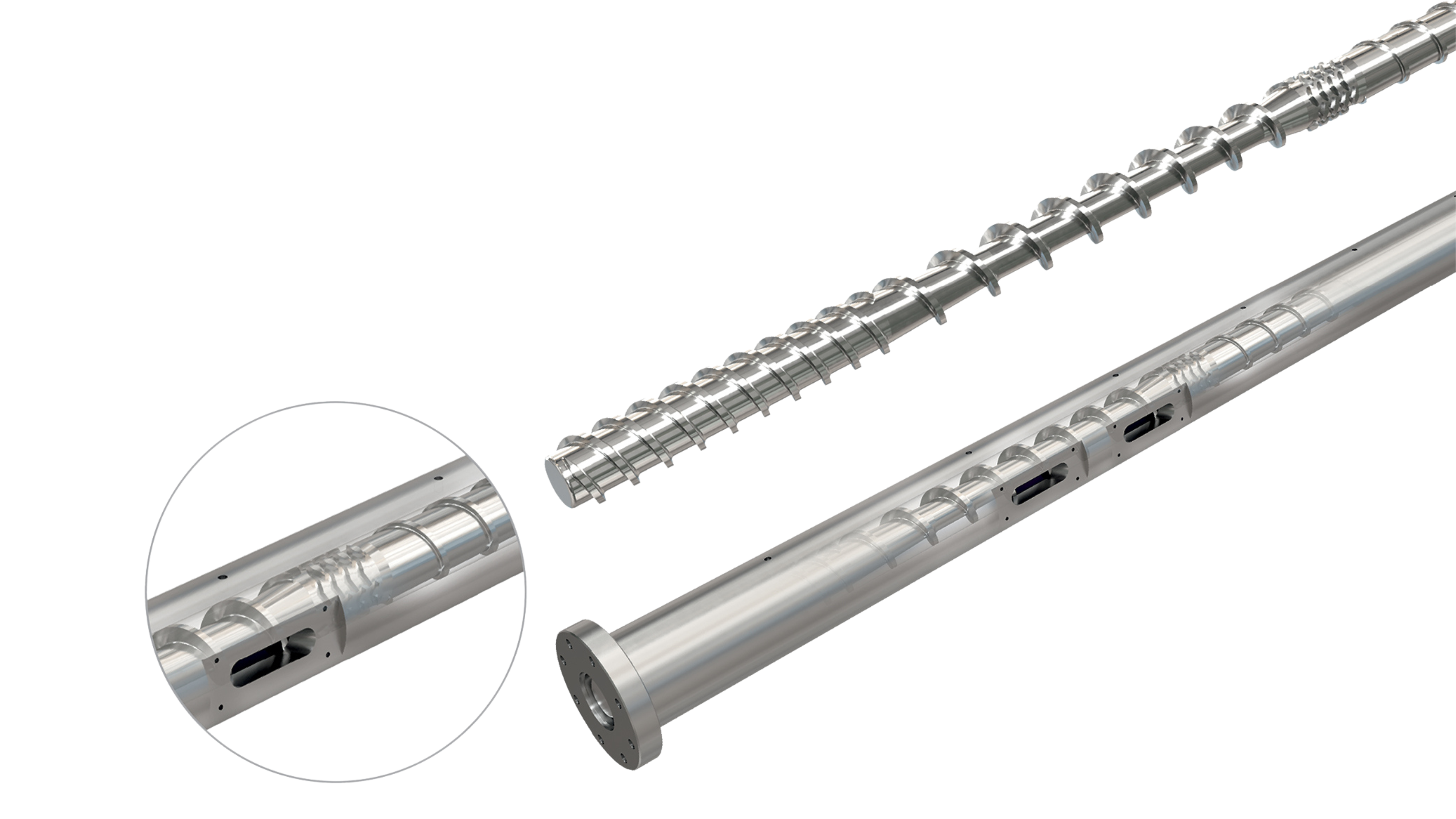

GROOVE FEED

| Material Grade | Sleeve Hardness | Hardness Depth |

| EN 41B | 65 – 68 HRC | 0.6 – 0.7mm |

| HSS M2 | 62 – 64 HRC | Through Hardened |

| D2 (HCHC) | 55 – 62 HRC | Through Hardened |

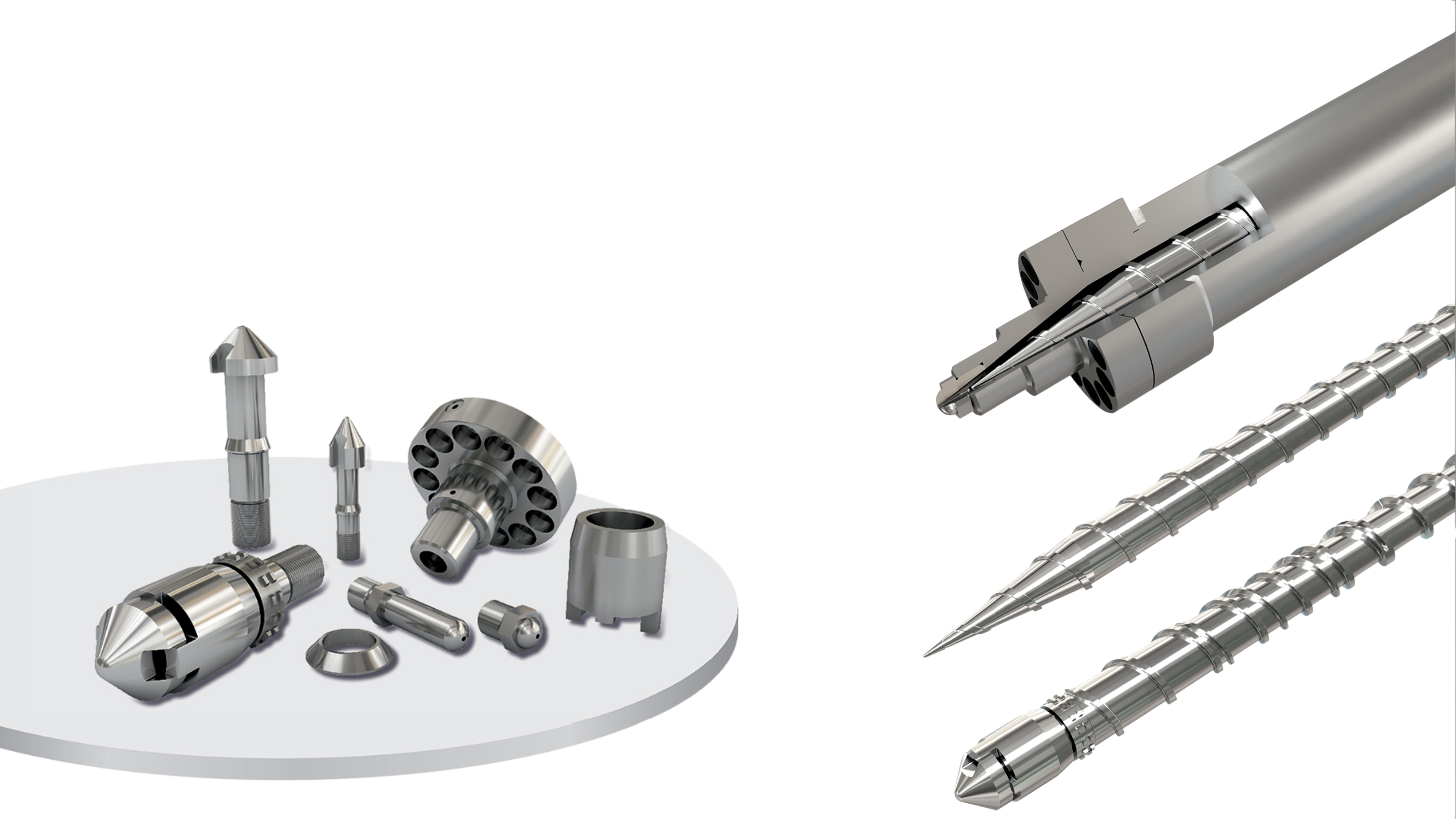

INJECTION MOULDING SCREW & BARREL

Kesar Extrusions offers a versatile range of Injection Moulding Screw and Barrel designed with cutting-edge technology. Available with various nitriding options such as gas and plasma, these screws and barrels meet diverse industrial requirements precisely. Built to client specifications with customized length-to-diameter ratios, they deliver optimal performance and user-friendly operation.

Bi – Metallic Coating:

| Tungsten (%) | Cobalt (%) | Hardness | Max. Service Temp. | Process |

80 to 84 | 11 to 13 | 70 HRC | 400 °C to 450 °C | HVOF |

Applications

Providing Performance Across Industries

PVC Pipe and Fittings

CPVC Pipes and Fittings

Sheet and Profile

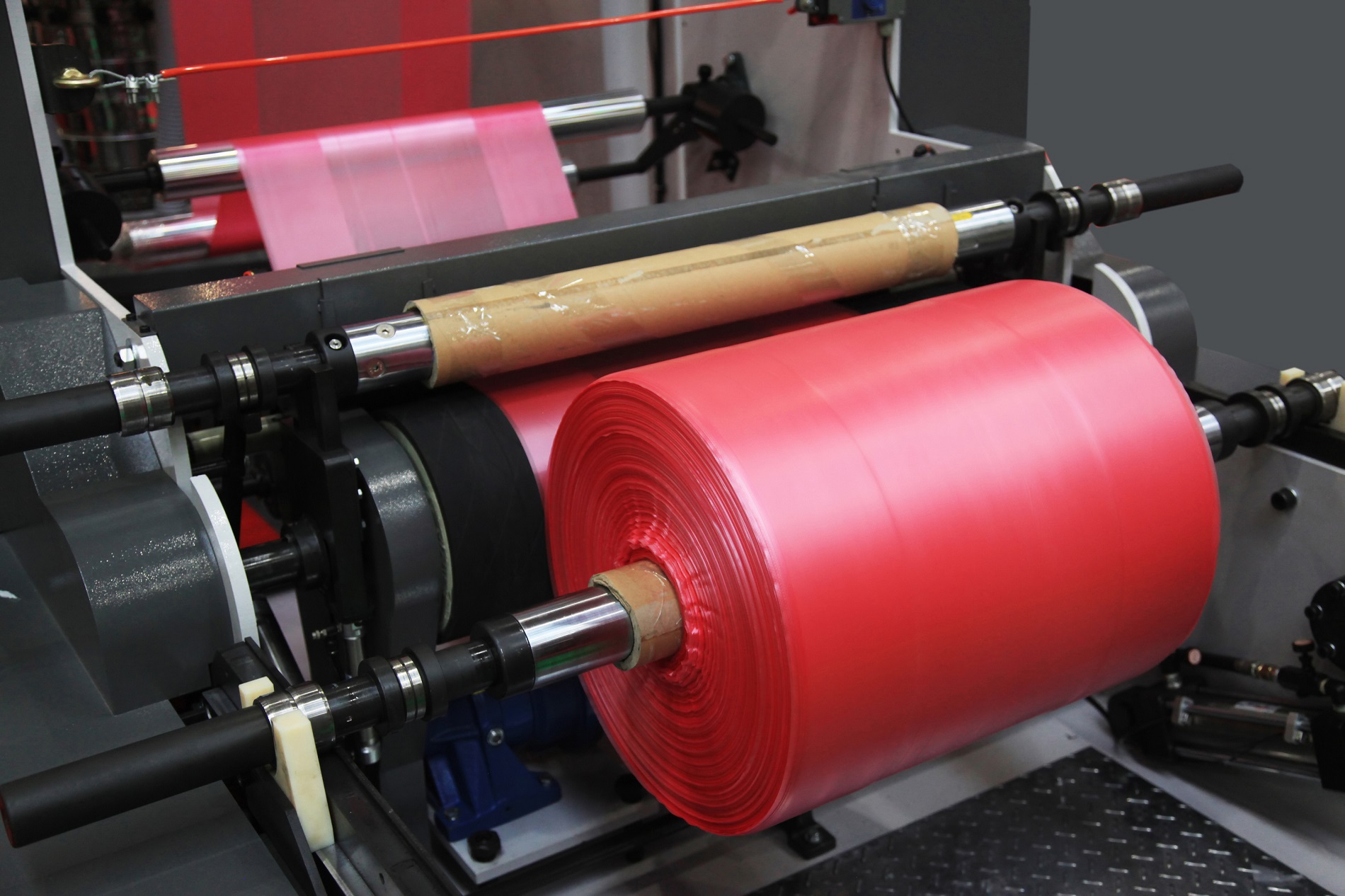

LDPE-HDPE-PP Film

HDPE Pipes

LLDPE Tubing

Raffia

Granules

Moulded Items

Cable

Monofilament

Blow Film

What Is Your Requriement?

Our extrusion systems serve a variety of industries, including plastics, packaging, machinery manufacturing, PVC and CPVC pipes, HDPE and LLDPE tubing, cable manufacturing, and more.

Kesar Extrusions specializes in manufacturing high-quality screws and barrels, including Single Barrier Screws, Parallel Twin Screws & Barrels, Injection Moulding Screws & Barrels, Conical Twin Screws, Maddoc Barrier Screws, and Bimetallic Screws & Barrels.

We have a rigorous quality control process in place, with multiple checks at various stages of production. Our team of quality auditors ensures that each product meets industry standards for durability, precision, and functionality.

Yes, we specialize in providing customized solutions tailored to meet the unique needs of each client, ensuring that our products fit specific machinery and industrial applications.

We use high-quality alloy steel and other durable materials, ensuring that our screws and barrels offer superior performance, wear resistance, and longevity.

Our products are designed for extended durability, thanks to the use of premium materials and advanced manufacturing techniques. Proper maintenance can further enhance their lifespan, ensuring long-term performance.

We are based in India and have a strong presence in both domestic and international markets, supplying our products to clients across various countries.

You can reach us via our Contact Us page on the website, where our team will be happy to assist you with any inquiries or support related to our products and services.